Article#: DGC/ART/009

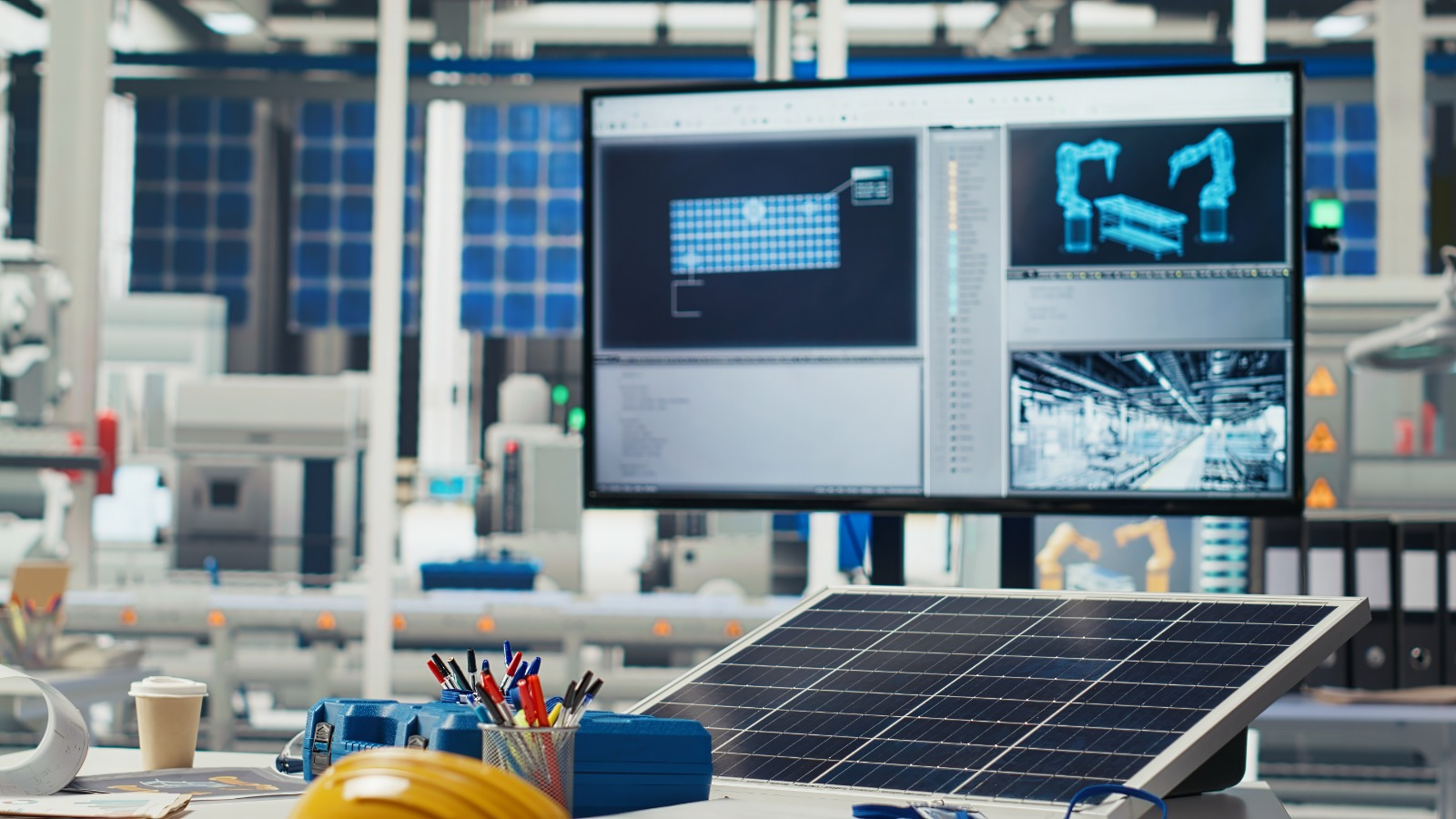

The global shift toward renewable energy has intensified the demand for efficient and scalable solar cell production facilities. Designing an industrial space optimized for solar cell manufacturing requires meticulous planning to ensure high productivity, energy efficiency, and seamless workflow integration. Here, we explore the essential design considerations to enhance operational success.

- Facility Layout for Process Efficiency

Solar cell production involves sequential processes like wafer cutting, doping, layering, and assembly. A well-structured layout minimizes material handling time, enhances operational flow, and reduces energy consumption.

- Adopt a linear production setup to streamline movement and eliminate bottlenecks.

- Allocate segmented zones for handling raw materials, fabrication, testing, and packaging.

- Controlled Environment and Cleanroom Standards

High-tech solar cell manufacturing demands precise environmental conditions to prevent contamination and defects.

- Implement ISO Class 5–7 cleanroom spaces for critical steps like cell coating and testing.

- Utilize HVAC systems with HEPA filters to maintain air purity and temperature stability.

- Material Handling and Automation Integration

Efficient material handling boosts production speed and reduces waste.

- Automated conveyor systems ensure smooth movement of wafers and components.

- Use robotic arms for precision assembly, reducing human-induced errors and enhancing throughput.

- Energy-Efficient Infrastructure

Solar cell production requires significant energy input, making efficiency a priority.

- Incorporate solar panels and energy recovery systems to power plant operations.

- Use smart lighting and insulation to reduce electricity consumption.

- Adopt waste heat recovery systems for optimized thermal management.

- Safety and Compliance Measures

Manufacturing solar cells involves handling chemicals and high-voltage equipment. Ensuring safety minimizes hazards and maintains regulatory compliance.

- Install fire suppression and chemical spill containment systems.

- Implement ergonomic workstations and automated safety checks to prevent workplace accidents.

- Align with international standards like IEC and ANSI for process compliance.

- Scalability and Future-Proofing

As solar technology evolves, manufacturing plants must remain adaptable to new innovations.

- Design modular production zones for seamless expansion.

- Plan for AI-driven monitoring systems to optimize future automation upgrades.

Conclusion

A well-optimized solar cell manufacturing plant must balance process efficiency, environmental control, automation, and energy sustainability. By integrating these key design principles, industries can reduce operational costs, improve product quality, and scale production effectively, supporting the transition to a greener future.