Article#: DGC/ART/002

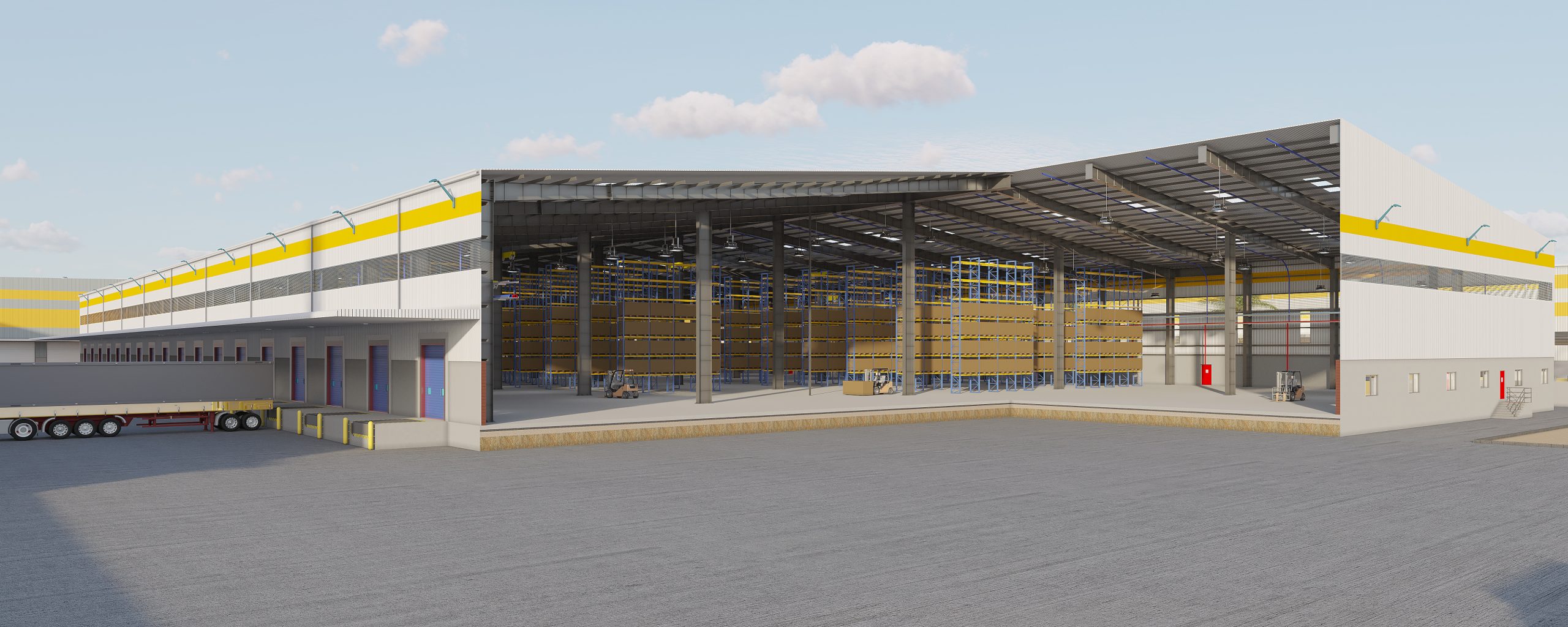

In the world of logistics and warehousing, efficiency is paramount. Built-to-Suit (BTS) warehouses are designed to meet specific operational needs, ensuring seamless workflow, maximized storage capacity, and improved handling times. By optimizing space planning, BTS warehouses deliver customized layouts

that enhance productivity and reduce operational bottlenecks.

1. The Importance of Tailored Warehouse Design

A well-planned warehouse layout directly impacts inventory management, order fulfilment speed, and overall logistics efficiency. Traditional warehouses often struggle with rigid designs that limit flexibility, whereas BTS warehouses are engineered to support specific business operations , from e-commerce fulfilment to cold storage distribution.

Key Benefits of Customized Space Planning:

- Efficient material flow and minimized handling time

- Reduced congestion in high-traffic areas

- Enhanced accessibility for both personnel and automated systems

2. Strategic Zoning for Optimized Workflow

BTS warehouse layouts typically incorporate strategic zoning , ensuring each section of the facility serves a distinct purpose. This segmented approach improves workflow and minimizes disruptions.

Common Zoning Strategies:

- Receiving & Inspection Areas: Placed near dock entrances for quick unloading and quality checks

- Storage & Racking Systems: Configured for optimal vertical and horizontal space utilization

- Packing & Dispatch Zones: Located close to loading bays to speed up shipment processing

3. Advanced Storage Solutions for Maximum Capacity

A key advantage of BTS warehouses is the integration of high-density storage solutions, allowing businesses to maximize available space without compromising accessibility.

Popular Storage Techniques:

- Automated Storage and Retrieval Systems (AS/RS): Enhances inventory accuracy and reduces labour dependency

- Dynamic Slotting Methods: Adjusts product placement based on demand fluctuations

- Multi-tier Racking: Optimizes vertical space for high-volume storage needs

4. Automation and Smart Logistics Integration

Modern BTS warehouses incorporate automation and IoT-driven solutions , improving operational efficiency and reducing reliance on manual handling.

Innovations Driving Warehouse Automation:

- AI-powered order-picking robots for faster fulfilment

- RFID tracking for real-time inventory visibility

- Smart conveyor systems that streamline material movement

5. Sustainability in Space Planning

Beyond operational efficiency, BTS warehouses also embrace sustainable space planning , incorporating eco-friendly materials and energy-efficient infrastructure.

Sustainability-Focused Practices:

- Solar-powered lighting & HVAC systems

- Waste reduction strategies through optimized material handling

- Water recycling methods for facility operations

Conclusion

Optimized space planning in BTS warehouses ensures customized efficiency, balancing storage density, workflow optimization, and cutting-edge automation. By tailoring layouts to industry-specific needs, companies can boost logistics speed, reduce costs, and improve overall warehouse performance.

For businesses looking to enhance operational excellence, investing in customized space planning within BTS warehouse designs is a strategic move toward long-term growth and efficiency.